We specialise in uv cured coatings due to such a large majority of our printed work being rigid plastics however liquid lamination can have some benefits for flexible and paper based materials.

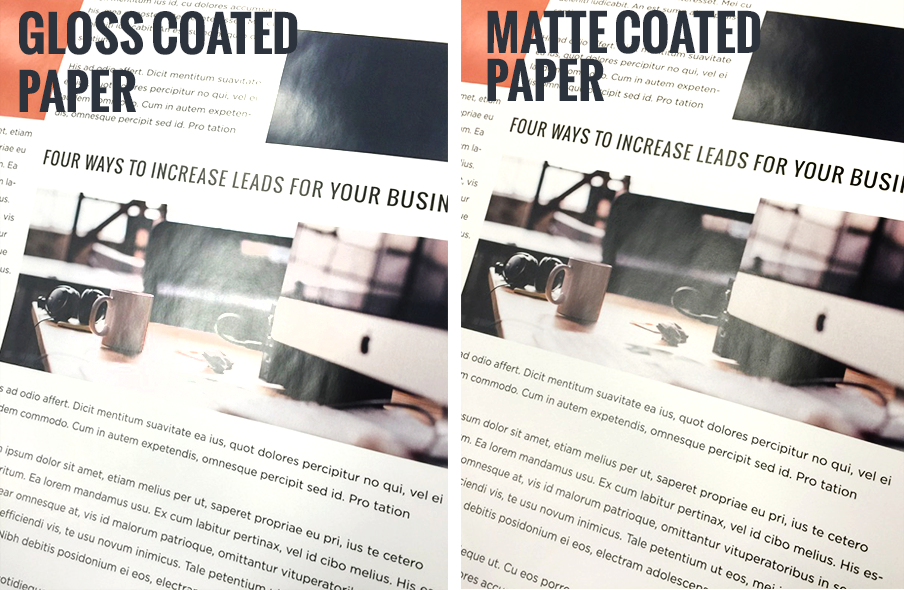

Coat paper vs gloss lamination.

Both add a good amount of durability to any digital printing project.

Gloss transparent and fashion feel.

Gloss provides a higher level of protection than matte and is easier to clean.

In this respect they can be viewed as flashy to their subdued matte counterparts.

Gloss lamination forms a protective coating over the print which makes it suitable for items such as menus etc.

For instance paper is perfect for hot melt lamination as it can withstand heat.

The coating can also be applied in numerous finish options such as.

So it really comes down to what you re trying to achieve.

Paper stock cover lamination headbands endsheets news events news events contact us february 3 2016 product features bridgeport national bindery inc.

So no matter you choose glossy or matte lamination they all have the advantage of lamination just different in appearance.

Gloss is more high profile it adds a high gloss sheen often used on brochure covers menus magazine covers or presentation folders.

Varnishes typically cost less than laminates but they also don t hold up as long.

It is definitely the high impact option.

You want the piece to make a strong visual impact.

In contrast to matte lamination the gloss has a lustrous quality as light bounces off the surface.

Matt massive and luxury feel.

Uv coating is a superior option to lamination due to the low cost per unit coupled with high output speed.

Low cost no additional.

The liquid coating is available in gloss or matte finishes and usually matches the underlying paper i e matte varnish for matte paper and glossy varnish for glossy papers.

The staff at westmount signs work as an.

Gloss laminated bags and magazines draw attention to themselves.

Therefore the effect is that of vibrancy better image contrast and more vibrant depth of color.

Cold laminate is used for the treatment of vinyl or other sign applications many cold laminates also have additional uv protection for outdoor use.

Apply a varnish over printed labels to seal and protect the ink and the label.

With gloss lamination the colors.

Pros cons of lamination vs.

Gloss dull or a special textured finish that is accomplished using a roller.