The best way to understand how much your air system is costing your business is to conduct a thorough audit to determine how much energy and power your compressors are consuming daily and discover where improvements can be made.

Compressed air audit procedure.

A team of experienced professional compressed air wizards will visit your plant spend days measuring pressures and examining your system and give you a list of all the things that are wrong.

Compressed air audit optimize your compressed air system owned and operated by marshall compressed air consulting.

Working closely with you to establish the most efficient way to minimize the cost of operating your compressed air system.

Audit the audit is where the project is created at a conceptual level.

How much does compressed air cost.

Compressed air efficiency fundamentals using compressed air audits to identify areas for.

Find out how i can help.

Performing a compressed air audit of your system is the first step in determining issues that could be hindering your unit s efficiency and unnecessarily increasing energy costs.

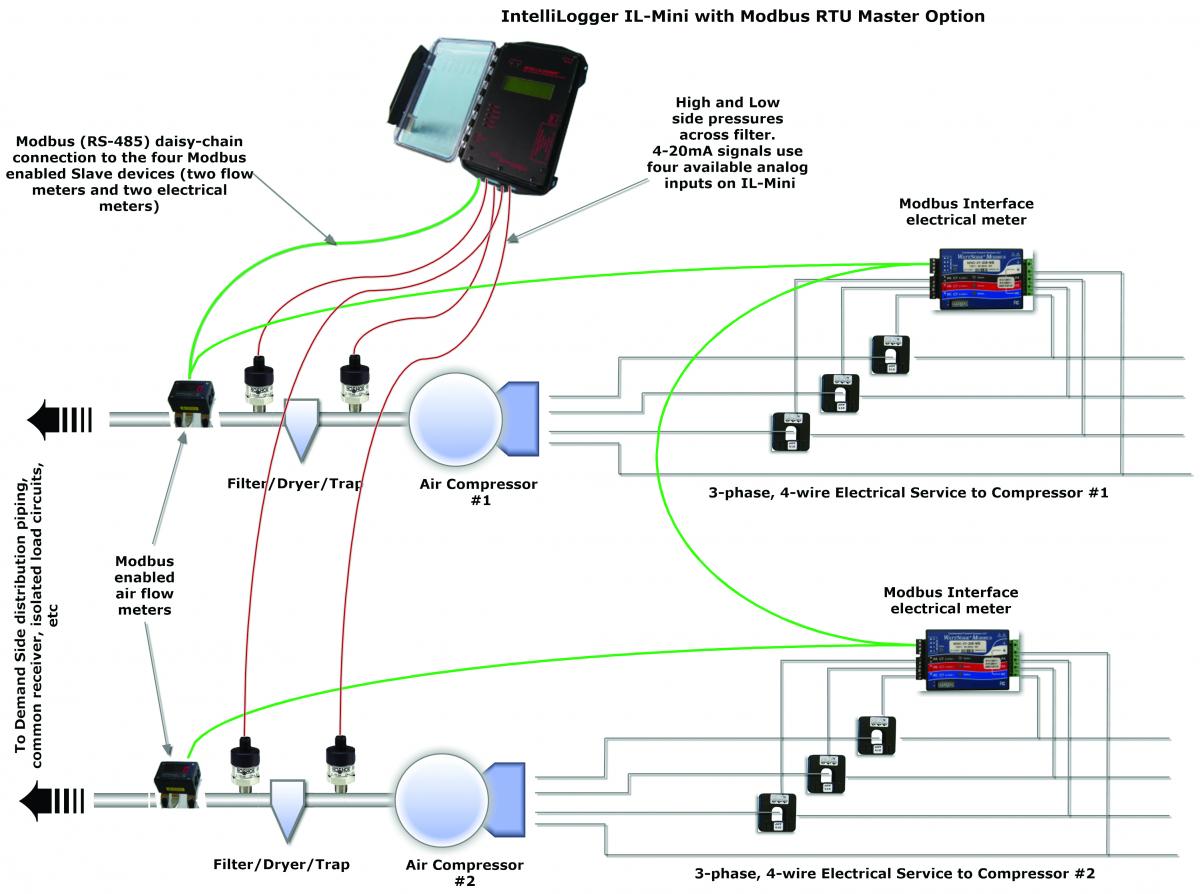

Measures the quality of the air including an assessment of any water or oil in the compressed air and draws comparisons to your specific needs at any point in the system.

Our detailed demand side audit and analysis can achieve savings of up to 50 in.

Blake pendleton s team of experts are well versed in the compressed air auditing process.

One of the most popular methods to do so is a comprehensive compressed air audit or air demand analysis.

Compressed air leaks alone account for 25 30 of compressed air use.

Savings are usually achieved by system performance optimisation leak reduction and practical air management processes.

Your nearest blake pendleton area manager will coordinate the ins and outs of an audit for you.

Read my latest articles.

Compressed air webinar hosted by ihs engineering 360 covering.

Improving the world through compressed air system optimization and training.

There are several levels of compressed air audits that can be performed walk through assessment system assessment or a full system audit.

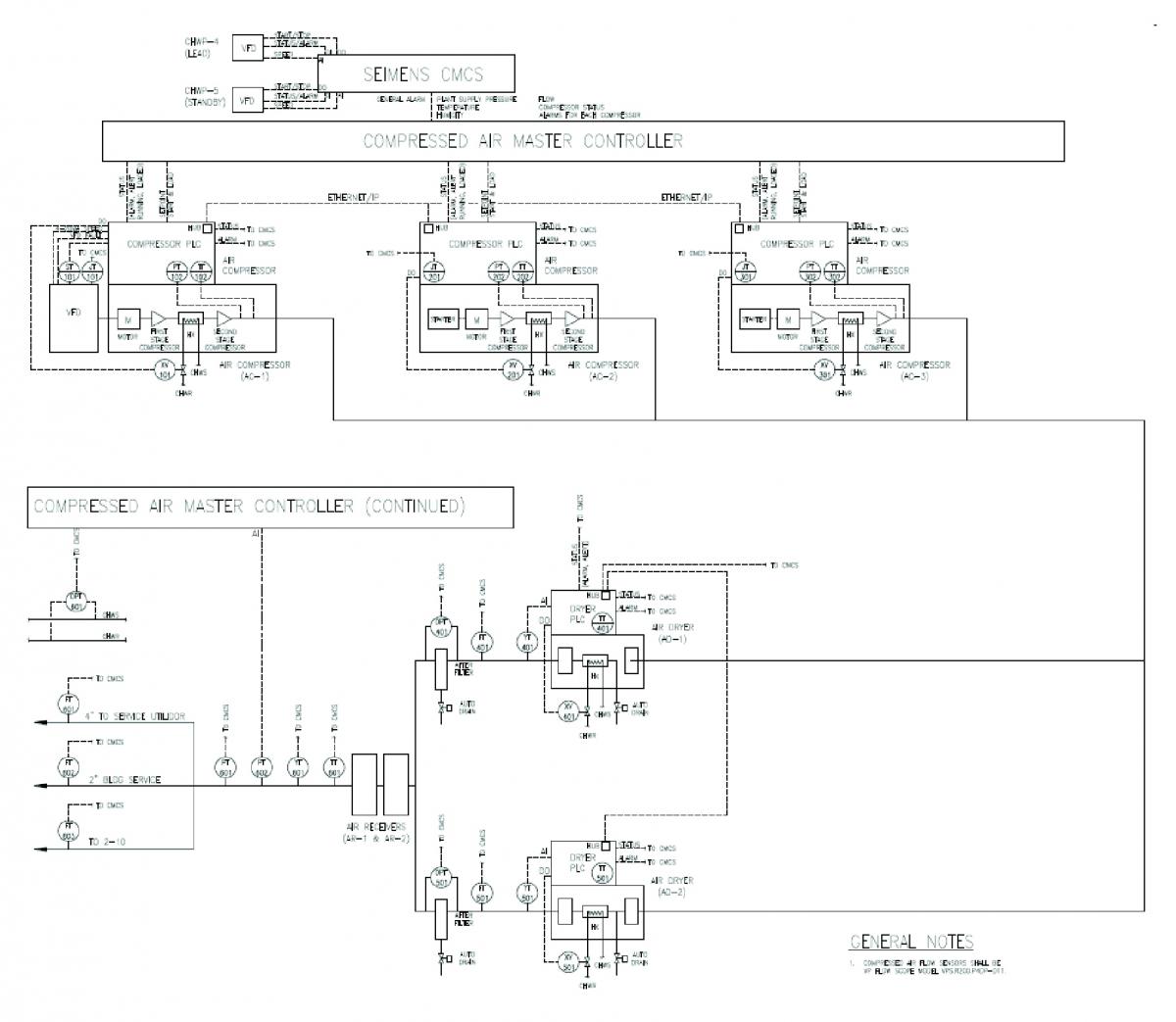

During the audit we dive deep into the supply and demand side of your compressed air system.

How air audit helps you reduce your cost of production air audit process can deliver energy savings of 30 and greater.